Titanium isn't just what we use - it's how we think.

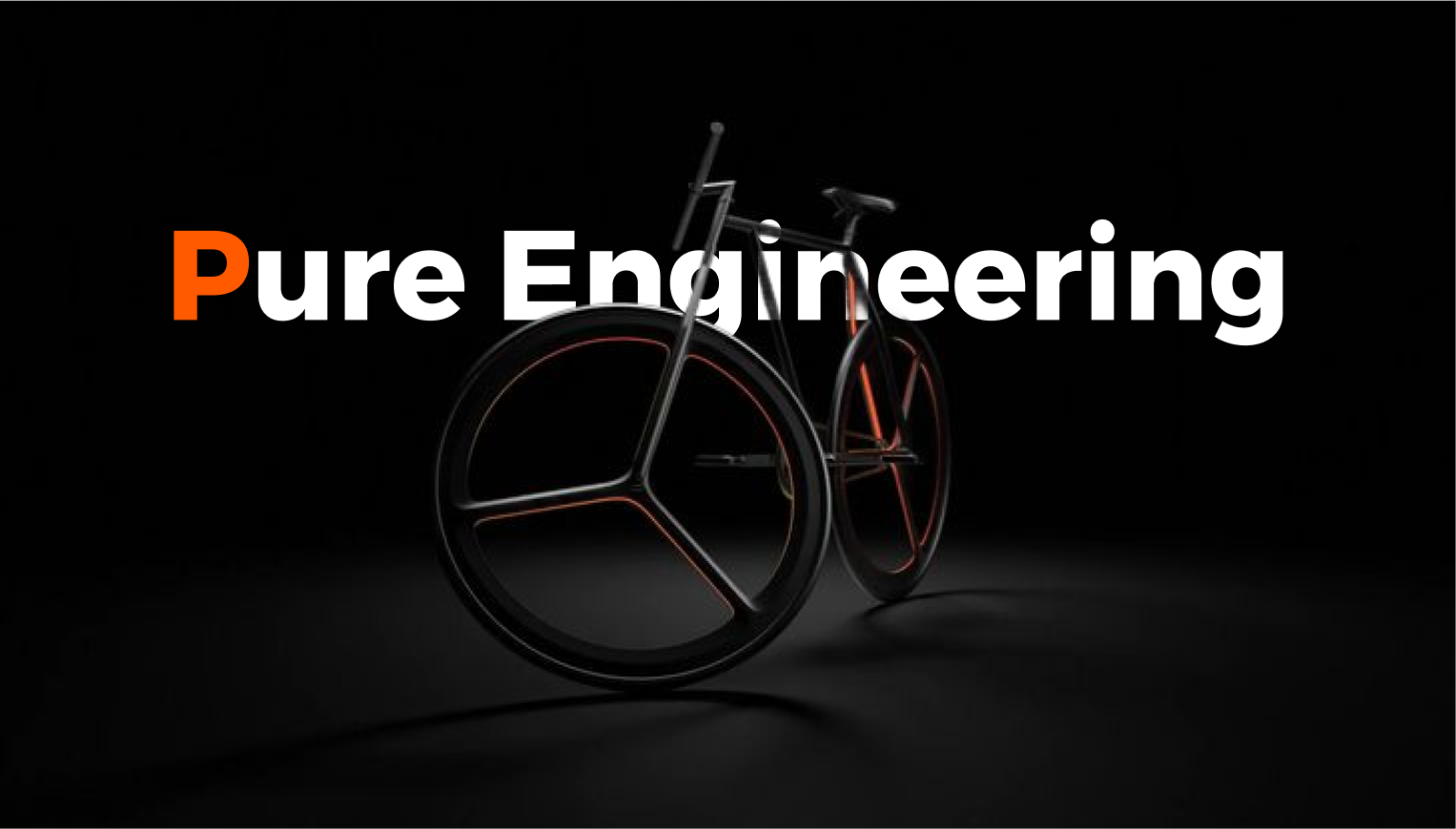

Every rider deserves material that refuses to compromise. Titanium delivers what others can't: the lightness of carbon with the soul of steel and the responsiveness of aluminum. This is engineering with purpose, where strength and elegance meet pure power delivery.

Precision-machined performance that never backs down.

Aerospace-grade Ti-6Al-4V titanium, meticulously machined for the ideal balance: featherweight construction, uncompromising power transfer, and geometry that puts every watt where it belongs. At Wert, we craft the foundation of your fastest self.

The Dawn of a New Era

The cycling industry stands at a crossroads. For decades, riders have had to compromise—choosing between weight and durability, performance and longevity, or innovation and reliability. Today, that era of compromise ends.

Witness the emergence of WERT Cycling, where titanium perfection meets uncompromising engineering.

Super lightweight, stiff power transfer, elegant design, ideal Q factor

Unmatched

At Wert, we machine every crankset from aerospace-grade Ti-6Al-4V, delivering race-ready performance without sacrificing long-term durability.

YOUR ARTISTRY, OUR ENGINEERING

BUILDER PROGRAM

Your frames deserve components that match their quality, story, and soul. Partner with WERT to offer your customers a drivetrain that completes their dream build.

The Visonary

Rico De Wert

The WERT story begins with Rico de Wert, a visionary who embodies a lifetime of cycling passion meeting uncompromising engineering. As an accomplished engineer and relentless perfectionist, Rico's philosophy is simple: create the absolute best, with no shortcuts and no compromises. WERT is the manifestation of this dedication, forged in aerospace-grade titanium.

The Wert Factor

WERT asks: Why compromise? Why choose between lightweight for road and durability for MTB when superior material, expertly engineered, delivers both?

Why accept planned obsolescence when components can last lifetimes? This questioning of norms drives our innovative spirit.